Drug Discovery

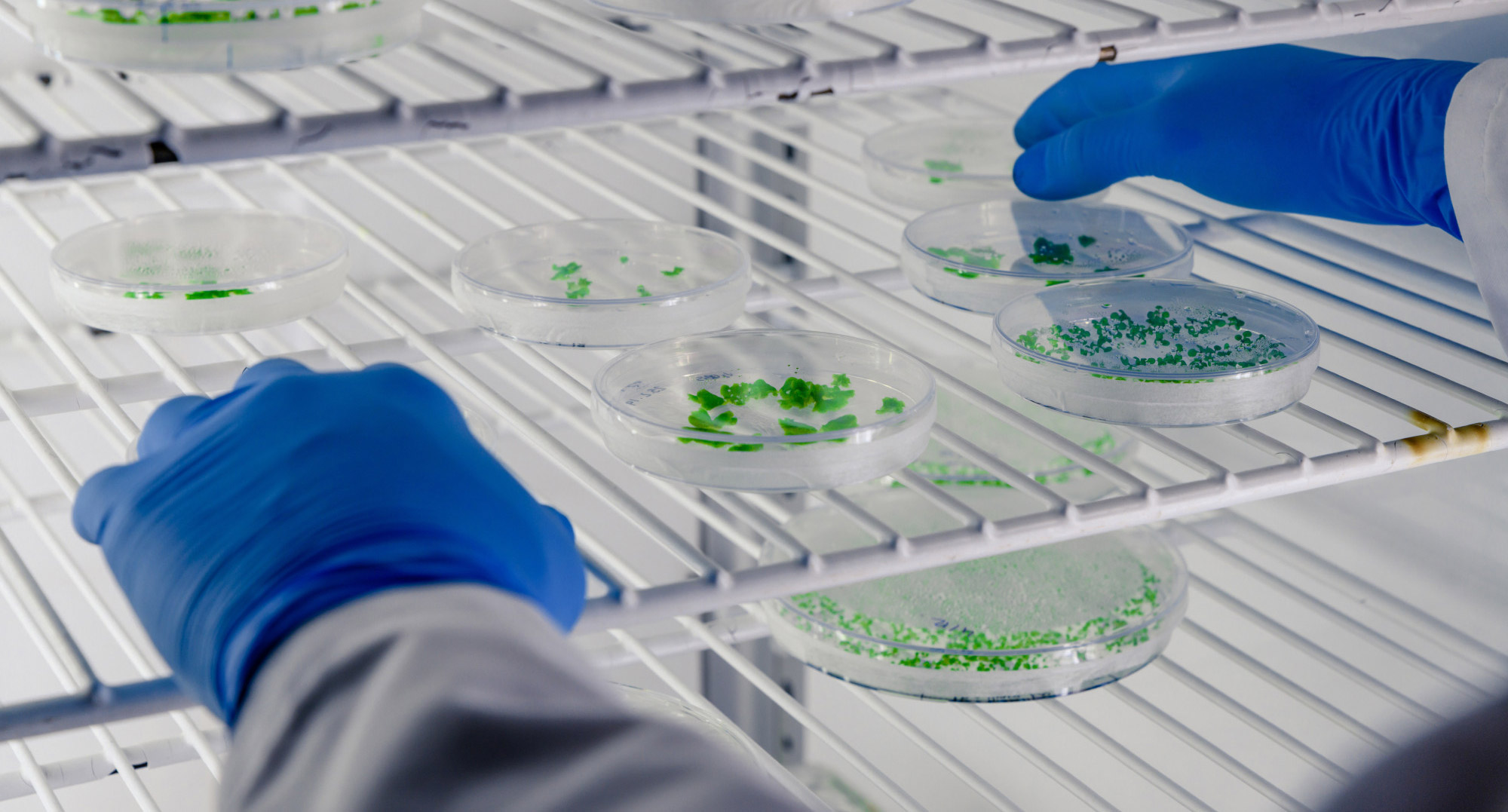

The trend in Drug Discovery business is focused on increasing efficiency and reducing costs through the use of innovative technologies towards developing more targeted therapies, including gene and cell therapies. There is also an emphasis on collaboration between companies, academic institutions, and government organizations to advance research and development. Additionally, there is growing interest in the active pharmaceutical ingredient industry for finding out the new synthetic pathways to get the active compounds for therapeutic uses. The active pharmaceutical industry is seeing a trend towards increased global competition, consolidation, and outsourcing. Many companies are investing in innovative technologies such as artificial intelligence and big data analytics to improve the efficiency and effectiveness of drug discovery and development. In terms of tools, the active pharmaceutical industry relies heavily on a range of technologies, including high-throughput screening, computer-aided drug design, genomics, proteomics, and bioinformatics.

Organic synthesis, purification and compounds identification are three critical steps in the production of Active Pharmaceutical Ingredients (APIs). Organic synthesis involves the chemical transformation of starting materials into the desired API through a series of reaction steps. However, the synthetic pathway often produces impurities, side-products, and residual reagents, which can be toxic, affect the quality of the product, or cause adverse effects in patients. Therefore, purification is necessary to isolate the desired product from impurities and ensure its purity, potency, and safety. Various purification techniques are used in API manufacturing, including crystallization, distillation, chromatography, and membrane filtration. These methods can effectively separate and remove impurities based on their physical and chemical properties, such as boiling point, solubility, or affinity to specific resins or filters. The purification step is critical for the success of the API manufacturing process since it affects the yield, quality, and cost of the final product. Insufficient purification can result in lower yields, decreased potency, or contaminated products, leading to additional processing steps, increased costs, or even batch rejection. Therefore, the organic synthesis and purification steps are interdependent and require careful optimization and control to achieve high-quality API products.